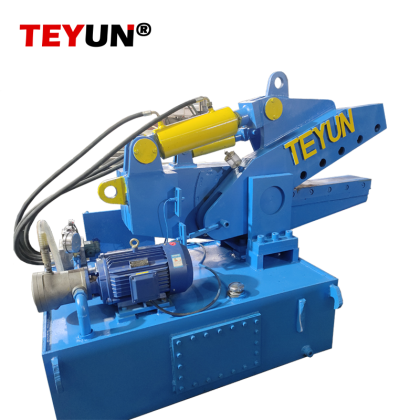

Máy cắt kim loại cá sấu

là một dụng cụ công nghiệp được sử dụng rộng rãi, được thiết kế để cắt nhiều loại tấm kim loại, thanh kim loại và các vật liệu khác. Được đặt tên theo hình dạng hàm cá sấu, máy này sở hữu cơ chế cắt mạnh mẽ, mang lại khả năng cắt hiệu quả và chính xác. Nhờ độ bền, tính đơn giản và hiệu quả về chi phí, máy thường được sử dụng trong các ngành chế tạo kim loại, tái chế, xây dựng và phá dỡ.

Các tính năng chính và nguyên lý hoạt động

Kéo cắt cá sấu hoạt động bằng lưỡi dao thủy lực hoặc điện, chuyển động như máy chém để cắt kim loại. Các thành phần chính của nó bao gồm:

1. Hệ thống lưỡi dao – Thường được làm bằng thép cacbon cao, lưỡi dao trên và dưới tác dụng lực cắt để cắt kim loại sạch sẽ.

2. Hệ thống thủy lực/khí nén – Cung cấp lực cần thiết để cắt trơn tru và đồng đều.

3. Bộ phận điều chỉnh chiều dài – Cho phép kiểm soát chiều dài chính xác khi cắt tấm kim loại hoặc thanh kim loại.

4. Bộ phận bảo vệ an toàn – Bảo vệ người vận hành khỏi tiếp xúc ngẫu nhiên với lưỡi dao đang chuyển động.

Máy hoạt động bằng cách kẹp chặt miếng kim loại tại chỗ trước khi lưỡi dao hạ xuống cắt xuyên qua. Không giống như các phương pháp cắt khác (như cắt plasma hoặc laser), cắt cá sấu không sinh nhiệt, lý tưởng cho các vật liệu dễ bị cong vênh dưới nhiệt độ cao.

Ứng dụng

-

Tái chế phế liệu kim loại – Cắt hiệu quả các phế liệu kim loại lớn, chẳng hạn như thép cây, ống và dầm, thành các kích thước dễ quản lý.

-

Chế tạo kim loại – Dùng để cắt tấm kim loại, sắt góc và các thành phần kết cấu khác.

-

Công việc phá dỡ – Giúp tháo dỡ các kết cấu kim loại một cách nhanh chóng và an toàn.

-

Ngành công nghiệp ô tô – Cắt các bộ phận kim loại trong quá trình tái chế và sửa chữa xe.

Thuận lợi

- Hiệu suất cao – Có thể xử lý khối lượng kim loại lớn một cách nhanh chóng.

- Bảo trì thấp – Thiết kế đơn giản với ít bộ phận chuyển động giúp giảm thiểu hư hỏng.

- Tính linh hoạt – Cắt được nhiều loại kim loại khác nhau, bao gồm thép, nhôm và đồng.

- Tiết kiệm chi phí – Chi phí vận hành thấp hơn so với phương pháp cắt nhiệt.

Những cân nhắc về an toàn

Người vận hành phải tuân theo các giao thức an toàn, bao gồm:

- Đeo găng tay và kính bảo hộ.

- Đảm bảo bảo trì máy đúng cách để tránh lưỡi dao bị cùn hoặc lệch.

- Giữ tay tránh xa vùng cắt trong khi vận hành.

Máy cắt kim loại cá sấu

là một công cụ thiết yếu trong ngành gia công kim loại, mang đến giải pháp cắt đáng tin cậy và hiệu quả. Thiết kế chắc chắn, dễ sử dụng và khả năng xử lý nhiều loại vật liệu khác nhau khiến nó trở thành một tài sản giá trị cho các doanh nghiệp xử lý và tái chế kim loại. Vận hành và bảo trì đúng cách đảm bảo hiệu suất và an toàn lâu dài.

Địa chỉ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Địa chỉ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский español

español العربية

العربية 日本語

日本語 中文

中文

Hỗ trợ mạng IPv6

Hỗ trợ mạng IPv6