Máy đóng kiện đứng là máy dùng để nén và liên kết các vật liệu như bìa cứng, giấy, nhựa và hàng dệt thành các kiện nhỏ gọn, dễ quản lý.

Đặc điểm chính của máy là quá trình nạp và nén theo phương thẳng đứng. Vật liệu được nạp vào buồng từ phía trên, và một xi lanh thủy lực mạnh mẽ sẽ ép xuống từ phía trên để nén vật liệu. Sau khi nén, vật liệu được buộc bằng dây hoặc dây đai để cố định hình dạng kiện.

Những máy ép kiện này phổ biến trong các môi trường như siêu thị, nhà kho và trung tâm tái chế vì chúng tiết kiệm không gian, dễ vận hành hơn và giá cả phải chăng hơn so với máy ép kiện ngang lớn hơn. Chúng lý tưởng cho các doanh nghiệp tạo ra khối lượng rác thải tái chế ổn định. Vậy làm thế nào để chọn máy ép kiện đứng phù hợp với bạn?

1. Xác định nhu cầu của bạn

Loại vật liệu đóng kiện

Giấy thải (bìa cứng, báo, sách, v.v.), màng nhựa, hàng dệt may, v.v. Mật độ và tính chất vật liệu khác nhau ảnh hưởng đến việc lựa chọn thiết bị.

Yêu cầu sản xuất

Chọn áp suất thích hợp (50-200 tấn) và kích thước kiện dựa trên khối lượng xử lý trung bình hàng ngày (tấn/ngày).

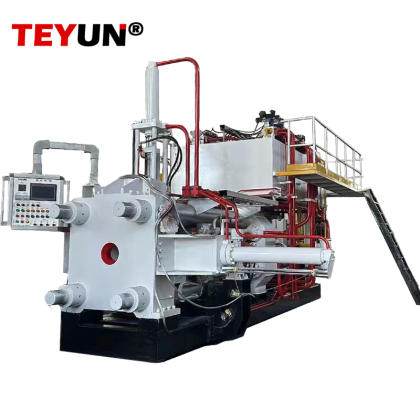

Mức độ tự động hóa

Thủ công (giá thành thấp, phù hợp với quy mô hoạt động nhỏ), bán tự động (nạp thủ công + nén tự động), hoàn toàn tự động (băng tải + điều khiển PLC).

2. Chất lượng của các thành phần chính

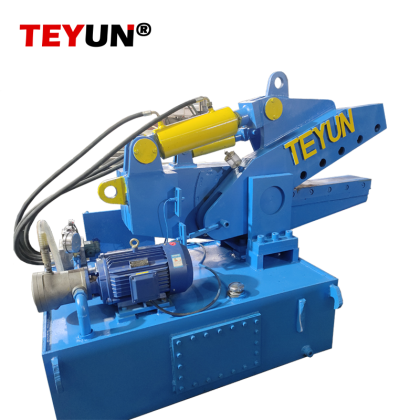

Hệ thống thủy lực

Tốt nhất nên chọn các thương hiệu uy tín. Kiểm tra phớt xi lanh và khả năng chịu áp suất của trạm bơm (≥25 MPa).

Cấu trúc khung

Độ dày tấm thép ≥16 mm. Mối hàn phải không có vết nứt để đảm bảo khả năng chịu áp lực và biến dạng lâu dài.

Mô-đun điều khiển

Khuyến nghị sử dụng PLC Siemens/Mitsubishi. Giao diện màn hình cảm ứng phải có chức năng tự chẩn đoán lỗi.

3. An toàn và Bảo vệ Môi trường

Các biện pháp an toàn: Nút dừng khẩn cấp, thiết bị bảo vệ quang điện và bảo vệ quá tải áp suất.

Kiểm soát tiếng ồn: Tiếng ồn khi vận hành ≤ 75 decibel (yêu cầu thiết kế cách âm).

Bịt kín đường ống dầu: Ngăn ngừa rò rỉ dầu thủy lực.

Nếu bạn không chắc chắn điều gì phù hợp với mình, vui lòng hỏi chúng tôi.

Địa chỉ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Địa chỉ : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

English

English français

français русский

русский español

español العربية

العربية 日本語

日本語 中文

中文

Hỗ trợ mạng IPv6

Hỗ trợ mạng IPv6